“When boundaries of your thoughts exceed you enter to new dimensions of perception”.

When technology & imagination meet, an extraordinary vision emerges which requires a platform to convert imagination into reality using technological skills.

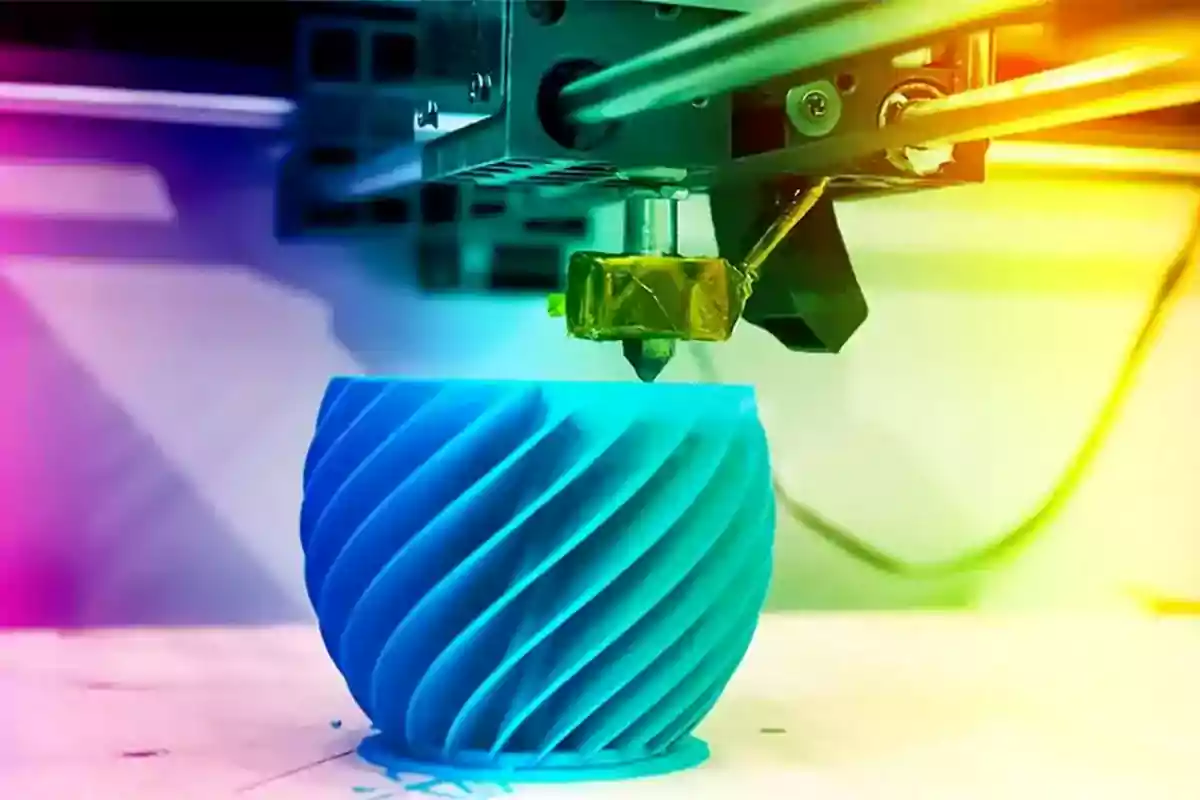

The idea of three-dimensional printing caused the same impact & gave a different dimension to the manufacturing industry by creating a link between the visual & real world. The concept of 3d printing is structured by many hands & brains but the father of 3d printing is considered as Dr. Hideo Kodama, & Charles hull. 3d printing is additive manufacturing which employes a group of techniques to quickly fabricate a scale model of physical assembly using 3d computer-aided design (CAD).

3d printing is often used interchangeably with additive manufacturing which explains the way a physical model is formed. The additive manufacturing prepares a model by adding the layers of respective material and solidify to structure a solid body.

General principles involved in 3d printing industry:

Modeling:

3d printable models can be created with the help of a computer-aided design (CAD) package, using manual methods similar to the sculpting process or via 3d scanners. In this process, geometric data is collected by analyzing the shape & appearance of the object to be fabricated. Although these manual & automated creation of 3d printing models are difficult for a layman to deal with therefore there are several applications available to generate the models such as shape ways, mini factory, fusion 360, Cura & many more.

Printing:

Before printing the 3d model from a. STL file must be processed & converted into a series of layers by using “slicer” this generates the g-code which are actual instructions to hardware to move in a specific direction, speed & other guidance.

3d printing enables the user to create almost any complicated geometry. The major disadvantage of this technique is time scale management which may exceed depending upon the shape & size of the object also the material used to develop the model.

Finishing:

Although the printing clarity & finishing yield by the 3d printing is sufficient & satisfactory, however for the high-resolution model may require the use of an application called “subtractive-manufacturing” that is CNC, or computer numerical control. Where the cost-effectivity may get affected due to large machines handling & management.

Processes :

The initial phase of 3d printing was much bulkier & expensive than that of the modern era. The simplification in 3d printing was introduced with different techniques like stereolithography, selective laser melting (SLM), fused deposition modeling (FDM), selective laser sintering (SLS), laminated object manufacturing (LOM).

3d printer material:

There are different materials employed according to the time, finishing, temperature, cost & environmental factors. Some of these are:

- Acrylonitrile butadiene styrene [ABS]

- Polylactic acid [PLA]

- High impact polystyrene [HIPS]

The complete technique consists of many many domains like electrical, electronics, mechanical, software, the combination of these all help to form a physical model from a geometric data.

3d printing contributed tremendously in the field of biomedical & proven itself as a boon for patients. Additive manufacturing also helped to reshape the manufacturing, construction, engineering of different complex geometries. The technique also helped to recover the monuments which can help to increase tourism.

The journey of dimension revolution doesn’t stop here, there are some more discoveries yet to be discovered with 4d & 5d printing concepts.